Machine Distributor & Master Controller for Roadheader Operation

• This Machine Distributor along with the Master Controller is a set of 2 flameproof enclosures that have been designed to perform the task of controlling and protecting the Road Header Machine. The Machine Distributor and Master Controllers are approved for use in Gas Group 1 in underground coal mines having high humidity and high presence of coal dust.

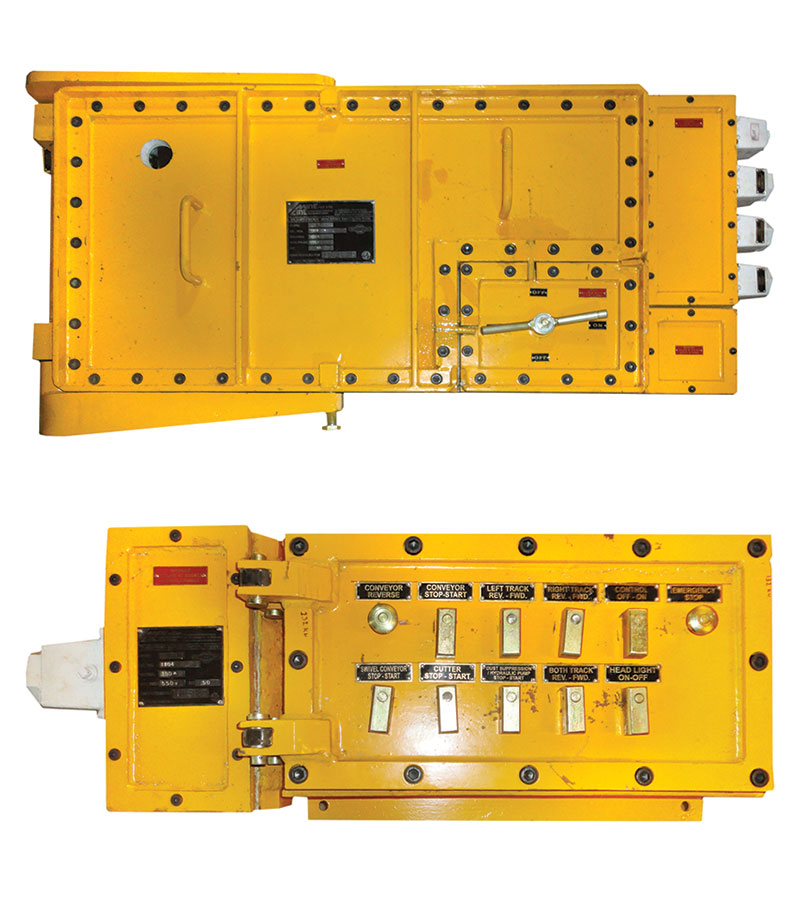

• This is the power controller which is fitted on the machine for distribution of the power to the different motors. One of the two individual compartments houses the Isolator, and the second larger compartment houses the contactors and protective relays which operate all the drives on the Road Header.

• Normally eight such drives are accommodated on the Machine Distributor. Each drive has its own individual protective relays and controls. These are called the Active Parts.

• The Machine Distributor Type MD-1 is a robust, welded, mild steel enclosure which is flameproof in design and divided into two compartments. This is the power controller which is fitted on the machine for distribution of the power to the different motors. One of the two individual compartments houses the Isolator, and the second larger compartment houses the contactors and protective relays which operate all the drives on the Road Header.

• The Master Controller Type MC-1 is a flameproof chamber which is placed near the Machine Operator of the Road Header. The various commands according to the sequence listed by the customer and in accordance with the machine requirements are possible by operation of the switches on the Master Controller.

• This enclosure is divided into 2 parts. One containing the relays for control and protection in precise sequence as requested by the customer choice and the other chamber houses the terminals for connecting the incoming & outgoing cables.

• The water pressure switch is a safety device flameproof in design which allows the cutter motor to operate only when the water pressure is sufficient in the system. It is a mechanical device vital for ensuring that the dusty environment is reduced during cutting.